Commercial Outdoor Furniture Trends & Specs

Your direct engineering resource for Heavy-Duty Umbrellas (Cantilever & Market), Luxury Outdoor Seating (Conversation Sets & Daybeds), and Garden Structures (Gazebos & Pergolas). Discover manufacturing standards and B2B procurement strategies.

Factory Advantage: Print BEFORE Sew (Cut-Piece)

Choosing the correct printing method is the critical defense against misaligned branding on custom umbrella canopies. Post-assembly printing often leads to distorted logos at the seams, resulting in rejected shipments and a loss of brand integrity for high-volume...

The Stem: Ensuring Your Umbrella Fits

Poor tube compatibility is a primary driver of customer returns and negative reviews in the patio umbrella category. A mismatched pole and base stem leads to wobbling, which customers perceive as a product defect. This simple specification error complicates inventory...

Granite vs. Concrete vs. Cast Iron

Choosing the right materials for an umbrella base directly impacts your damage-on-arrival rates and customer complaints. While a consumer might want the visual appeal of granite, an importer sees the risk of fractures in transit. Similarly, the classic look of cast...

Mobile Bases: Heavy-Duty Wheels

Substandard Mobility in heavy commercial umbrellas leads directly to property damage claims. Opting for bases with cheap, hard plastic wheels may lower the FOB price, but this choice risks scuffing expensive hotel decking, costing far more in returns and damaging your...

Cantilever Anchoring: The Counter-Balance

The offset design of a cantilever umbrella generates a constant tipping force, or torque, that wind dramatically multiplies. For common 8 to 13-foot commercial models, this leverage effect requires a massive base—often exceeding 400 pounds—to prevent catastrophic...

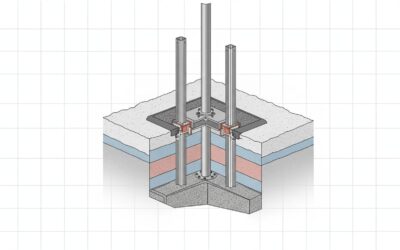

Factory Solution 3: In-Ground Mounts (Perm)

When a project site faces 130 mph wind loads or snow accumulation exceeding 70 psf, standard roof mounts fail. This isn't a matter of preference; it's a structural liability. For challenging terrain or compromised roofs, **in-ground mounts** are the mandatory...

Factory Solution 2: Empty Shells (Fillable)

The logistics of shipping heavy, pre-weighted bases directly erode profit margins. In a direct project comparison, a traditional mild steel solution costs $299,000, whereas an equivalent high-density polyethylene (HDPE) fillable base solution costs just $129,382. This...

Deck Mounts: Bolting to Wood & Concrete

When a deck mount is part of a life-safety system, the margin for error is zero. An installation failure isn't an inconvenience; it's a critical event. Structural anchors for fall arrest must withstand a minimum of 13.5 kNm of moment and 12.0 kN of vertical...

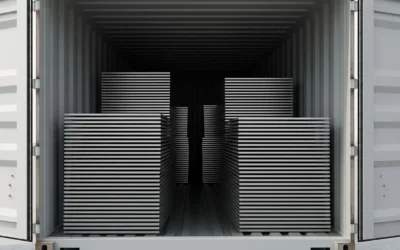

Factory Solution 1: Stackable Steel Plates

Heavy industry leaders are cutting transport costs by as much as 20% by shifting high-volume freight to rail and implementing data-driven logistics. These savings are not theoretical; they are the direct result of optimizing the entire steel base supply chain, from...